MSE

Outline

Evaluate thin films by the newest physical evaluation method.

Slurry (water and solid particle mixture) were mixed with compress air

in the nozzle and eventually injected on material surface at high velocity.

Injected slurry on material surface resulted, a wear progression (wear

rate) proportionately to the erosion (a strain/ scar occurred at the surface

by particle collusion) strength of the material.

It is a new type of solid particle impact test (slurry jet) to swiftly

evaluate wear properties of various material especially hard coated thin

films.

■Features;

- ・The accurate measurement of 1 µm less or equal thickness of difficult domain on thin films.

- ・The continuous measurements of wear intensity from material surface until base material.

- ・The accurate measurement of super hard coated thin film such as DLC.

■Applications;

- ・The new evaluation for the research and development of coated thin films field.

- ・New material properties evaluation field.

- ・New method of evaluation of hard coated thin films.

- ・The evaluation of the production technology quality.

Pamphlet(PDF)

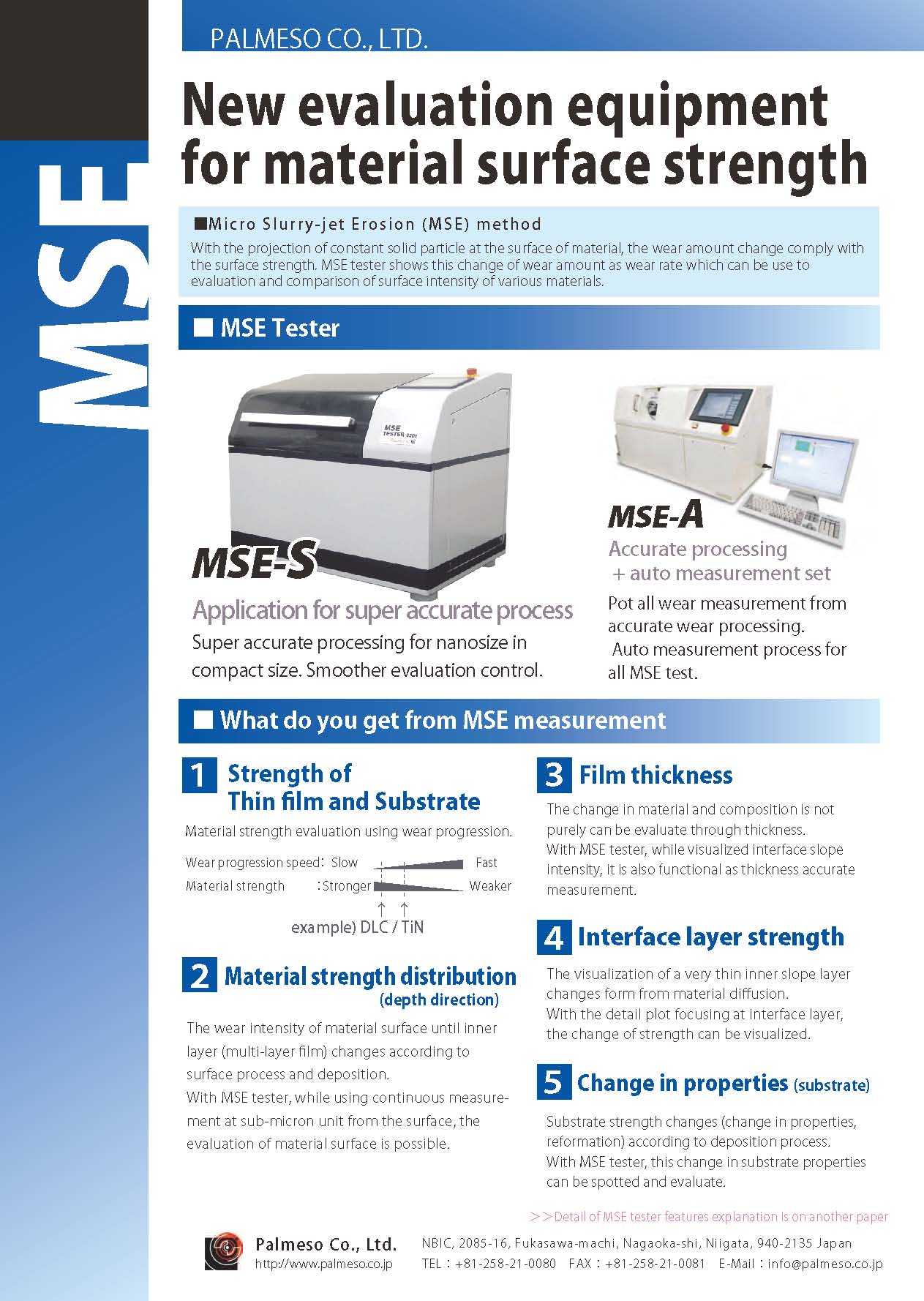

■New evaluation equipmentfor material surface strength

■Features of MSE tester

・Features of MSE tester

・MSE data characteristic

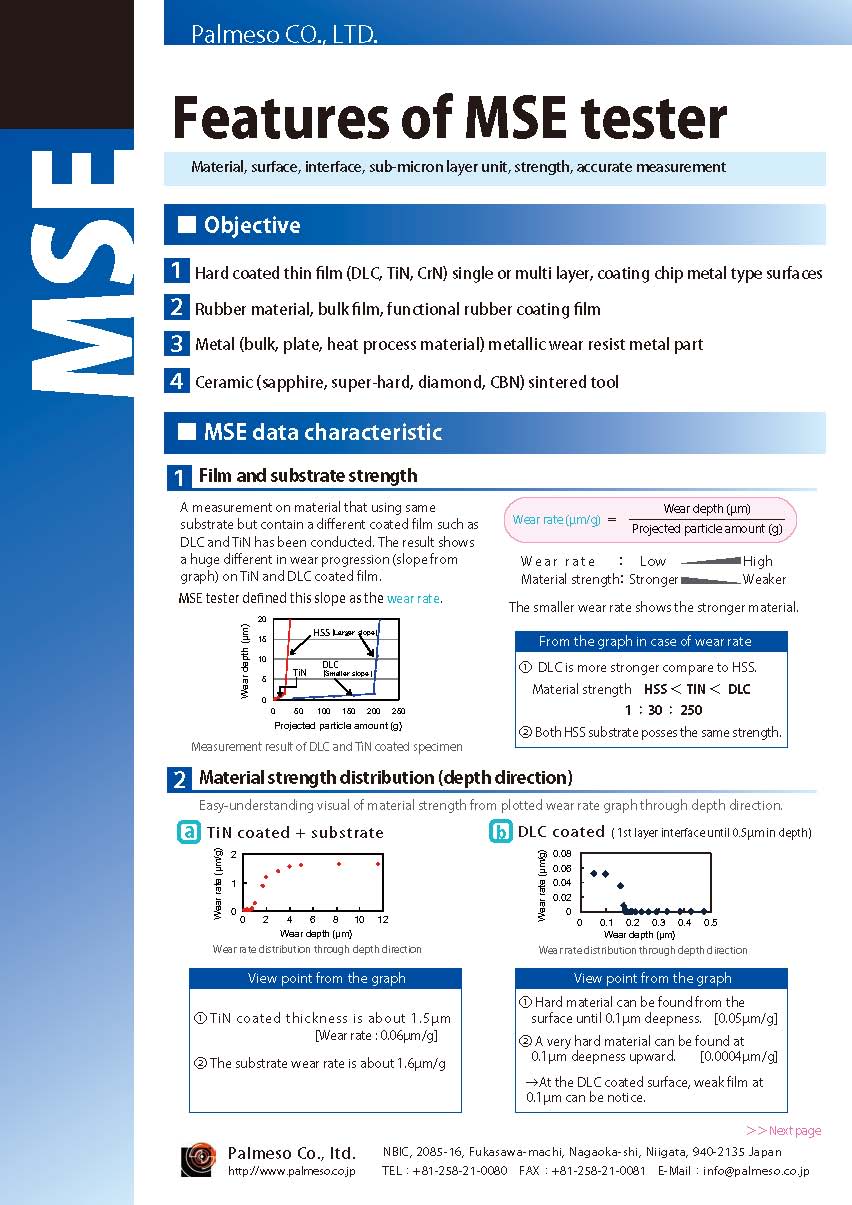

1. Film and substrate strength

2. Material strength distribution (depth direction)

3. Film thickness

4. Interface layer strength

5. Change of properties (substrate)

Academic-industry partnership with Fukui University.

- 1.Quality evaluation of thin film

- 2.hard coating material evaluation

- 3.Continuous evaluation from surface to base material

- 4.High resolution capability for hard material

- 5.Fast measurement

- 6.Evaluate all result in manufacture process

-

- 1.Research and development field

- a.Lifetime prediction references for cutting or grind tools

- b.New hard coated thin film material development field

- c.Hard novel material development field

- d.Thin film manufacture process development field

- e.Sintered material manufacture process development field

- 2.Manufacture field

- a.Variation inspection of manufacture equipment quality

- b.Indirect equipment maintenance by time-series test

- c.Quality guarantee

- ○ Test method

- ○ Type of evaluation

- 1. Wear rate measurement

- 2. Continuous measurement of wear rate at depth direction from surface to base material

- 3. Specific thickness evaluation of thin film

- ○ System structure

- ○ Wear mechanism

- ○ Wear mode