MSE

Wear test

There are two big categories concerning wear test.

1) Friction, wear test.

This test form by lapping two materials and from its surface decreased condition, the wear rate is evaluated. It is also can be use to evaluate oil efficiency by inserting the oil between the two materials.

This kind of test principle can be use with a number of combinations such as a planograph, a rod and a sphere according to one purpose.

2) Particle wear test.

There are two different types concerning this test that is;

- a) While scratching the pinching particle between two materials.

- b) While impact the particle to generated wear.

By choosing the specific solid particle, the intensity strength of materials roughness can be decides rather than wear or friction of the materials.

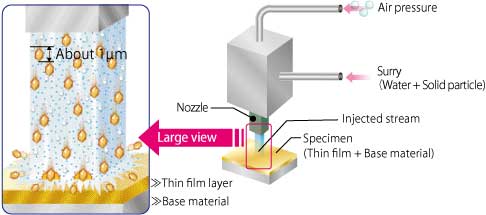

■ MSE wear test

Solid particle impact method is classified as [particle wear test].

Merit of this method is while impacted a large amount of the solid particle (about 1μm) for a short time, some difficult material such as a very thin coated film (less than 1μm), very hard material (diamond), and also very soft material (rubber), can be evaluated in less time.

By generates wear using stabilized continuous force, wear rate of the material can be measured. Furthermore, the wear rate contribution on innards and surface, movement change of base material and coating relation, research of similarity of large surface can also be apply through this measurement method.